Fluidized bed systems are in general viable for different types of fuels, and CLG may be particular suited for fuels with a high content of impurities. Hence, biogenic residues from agriculture and forestry could be applicable as a cheap and abundant feedstock for biofuel production using CLG.

In particular, cereal straw is an attractive lignocellulosic material, since it is one of the most abundant renewable resources, however, biogenic residues such as straw, have undesired properties with respect to gasification in fluidized beds:

- Low energy density leading to increased costs for transport and problems with feeding

- Low ash melting point leading to agglomeration and slagging

- High content of volatile inorganics like alkali and chlorine that promote corrosion and fouling

This makes it difficult to handle, transport and store efficiently, thus limiting its commercial use. Hence, it is necessary to perform some pretreatment of the feedstock prior to the gasification step.

The CLG process is in many ways highly applicable for processing residues with higher contents of corrosive components, such as chlorine, since the emissions are concentrated to one reactor, and the air reactor should be free from corrosive compounds. Furthermore, the CLG process could have some inherent advantages in handling these types of fuel since the presence of oxygen carriers under reducing conditions could affect the chemistry of impurities in many ways. Still, there could be issues regarding oxygen carrier interactions with trace elements as well as agglomeration and fouling in the fuel reactor. Thus, it may be necessary to address this with proper pre-treatment of the feedstock in order to optimize performance. The following methods for pre-treatment of biogenic residues are considered within this project:

- Drying increases the heating value of biomass, hereby improving the cold gas efficiency and the yield of H2 and CO in gasification.

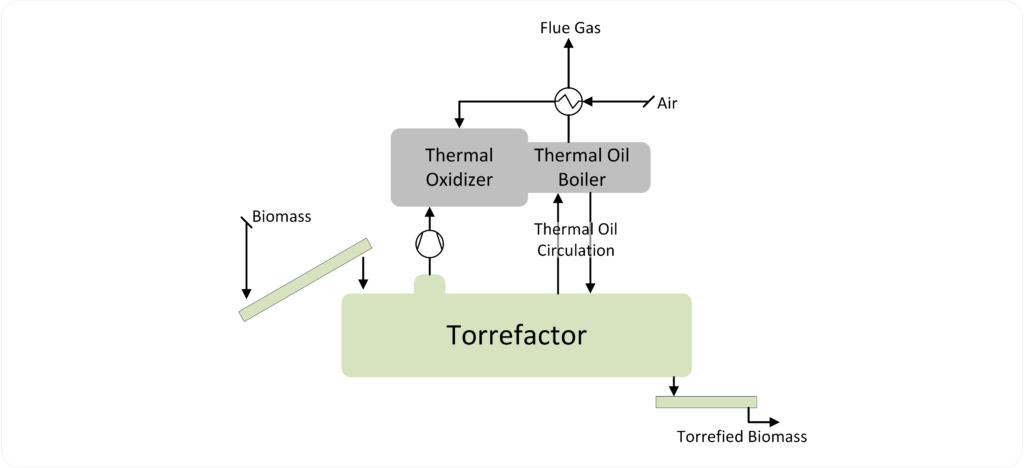

- Heat treatment (such as torrefaction) further increases the heating value due to the release of low calorific value gases that can be combusted to provide the heat for the torrefaction process, so that this process can be operated in a self-sustained manner. This process has also the potential to improve biomass ash melting behavior for gasification and to reduce the contaminants content: a significant fraction (10-50 %) of straw chlorine is volatilized together with some nitrogen and sulphur. The reduction of sulphur and nitrogen content could have a positive effect on downstream syngas cleaning requirements.

- Leaching of biomass could reduce the chlorine as well as the alkali content even further.

- Additives like slagging inhibitors in the pelletization process could increase the ash sintering temperature of biomass. Furthermore, additives can significantly reduce the release of detrimental inorganics.

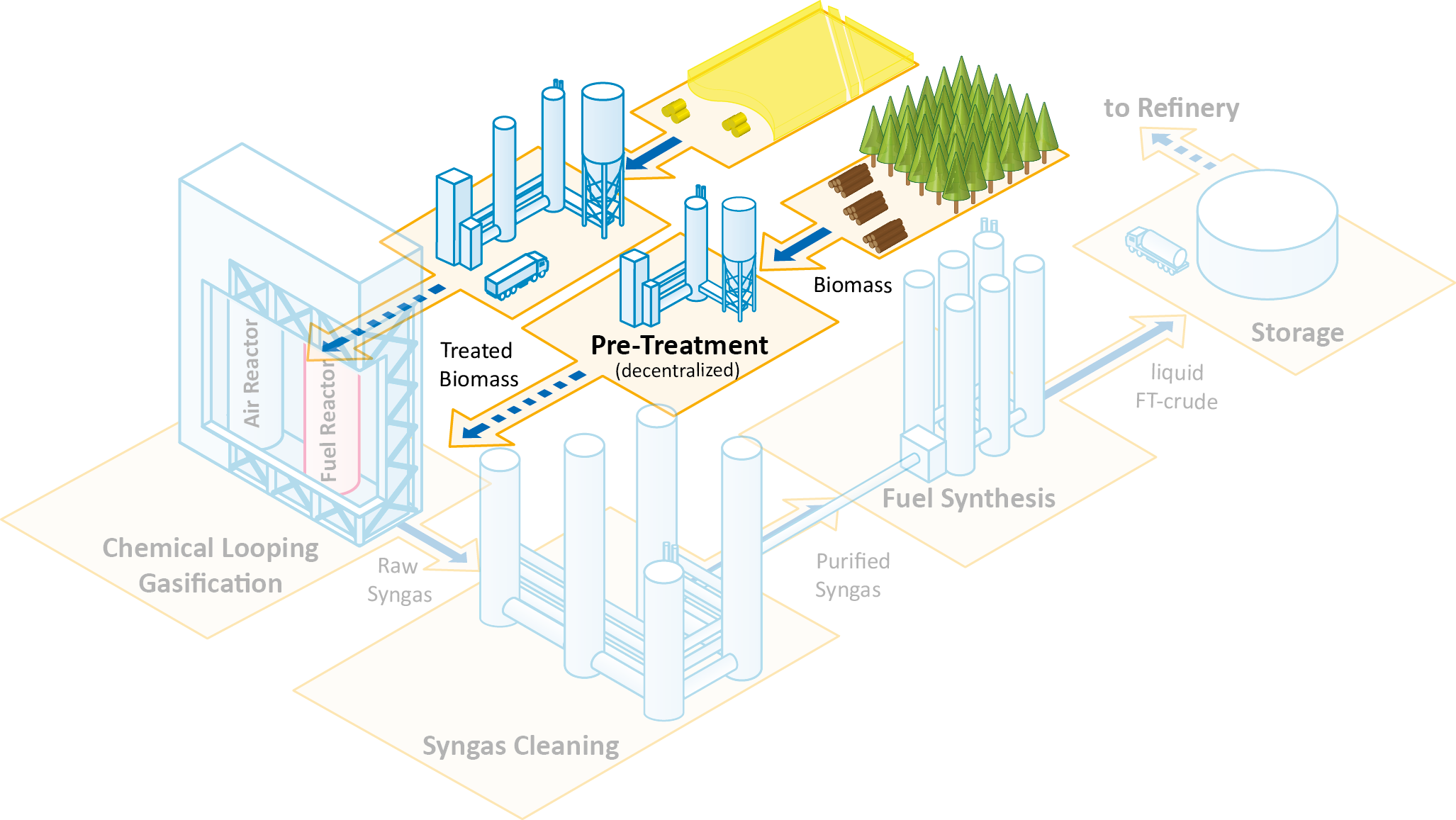

- Pelletization will raise the volumetric energy density of the feedstock and improve its handling properties, which will facilitate gasifier feeding and gasification process control, improving process reliability and reducing inert gas consumption in the feeding system. The use of pellets may allow for a decentralized pre-treatment of biogenic residuals using small units in rural areas and a centralized conversion of the pre-treated feedstock in large, efficient units (5-10 pelletization units may serve one gasifier).

These pre-treatment methods bring additional energy requirements, costs, and risks/uncertainties. Hence, the pre-treatment technologies applied in the scope of CLARA need to be optimized for each type of feedstock with respect to the economic and environmental performance of the whole biomass-to-end-use chain. It is expected that residues from forestry can be utilized in a chemical looping gasifier with limited pre-treatment (except for pelletization, if it needs to be fed to a pressurized system), whereas straw most likely requires a tailored combination of the methods mentioned above.