The CLARA EU H2020 Project focusses on elevating the complete biomass-to-biofuel process, described in The Concept, to market maturity. For this task, both the experiments and simulations of the process are crucial for the success of the project.

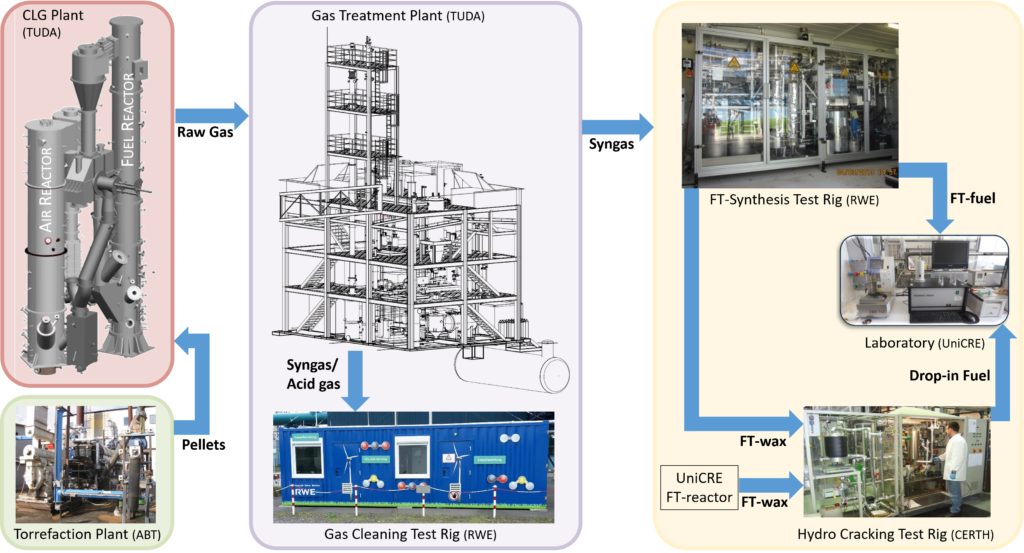

Regarding the experimental research, the entire biomass-to-biofuel process chain is to be investigated in pilot scale. A schematic depiction of the complete pilot scale process configuration is shown in Figure 1.

The 1 MWₜₕ pilot plant located at TUDA, which was erected in 2010 within the framework of COORETEC – LISA, forms the core of pilot plant configuration. It allows for semi-industrial investigations in the fields of combustion, CO2 capture and gasification and is unique in its dimension and design. The modular design of the plant, consisting of the three core components, a 1 MWₜₕ combustion chamber and two circulating fluidized bed reactors (CFB 400 and CFB 600), facilitates the implementation and investigation of different processes such as Carbonate Looping, Chemical Looping, and High Temperature Winkler Gasification (HTW) through an appropriate interconnection with additional components.

For the CLARA project, the pilot plant, configured in a chemical looping setup, will be coupled with a novel gas treatment plant, which facilitates a treatment and purification of a slip stream (approx. 200 Nm3/h) of the raw syngas formed inside the fuel reactor (=CFB400) of the pilot plant. Furthermore, containerized test rigs, provided by RWE, will be embedded into the gas treatment plant, allowing for a downstream processing (e.g. syngas fine cleaning and fuel synthesis) of the gases originating from the gas treatment plant.

In a final step, the synthesized fuels and waxes will be further analysed and processed in test facilities of CERTH and UniCRE, allowing for an in-depth investigation of the final end-products of the biomass-to-liquid process chain.

Preparation of the biogenic feedstock required for pilot testing will be conducted in the facilities of ABT, yielding a pre-treated, transportable feedstock in pellet form, fulfilling the designated process requirements (e.g. ash melting behaviour).