The project pilot plant for the industry-relevant-environment experiments will be constructed at the Technische Universität Darmstadt and will be constituted by two main parts, as shown in Figure 1: the chemical looping gasification (GLC) plant and the gas treatment plant.

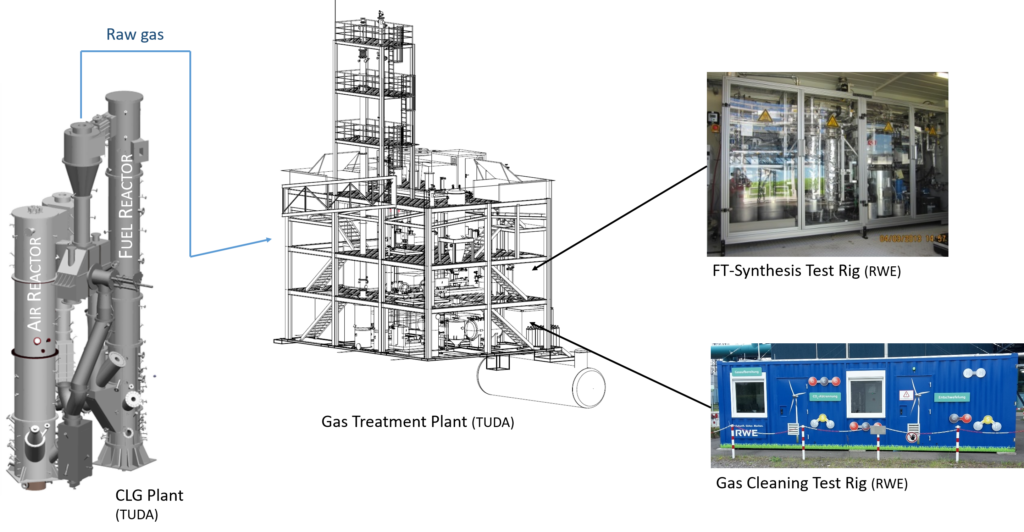

First of all, the existent 1 MWₜₕ pilot plant, where the chemical looping gasification (CLG) will take place, forms the core of the project pilot plant. This 1 MWₜₕ facility, shown in Figure 2, was erected in 2010 within the framework of COORETEC – LISA. It was afterwards used in SCARLET project in 2017 and is currently being adapted and expanded for the upcoming investigations of the COORETEC – FABIENE project and the LIG2LIQ project. The modular concept that was implemented allows for semi-industrial investigations in the fields of combustion, CO2 capture and gasification, and is unique in its dimension and design. Its main three components, shown on the left side of Figure 1, are a 1 MWₜₕ combustion chamber and two circulating fluidized bed reactors, the CFB 400 (Air Reactor) and the CFB 600 (Fuel Reactor). Different processes may be implemented and investigated in this plant, such as Carbonate Looping, Chemical Looping, and High Temperature Winkler Gasification (HTW).

Within the frame of the CLARA project, this pilot plant will be adapted with interconnections and additional components, in order to achieve the appropriate configuration for the chemical looping process being investigated.

Secondly, for the treatment of the raw syngas produced by the CLG pilot plant, a Gas Treatment Plant will be constructed. This plant will carry out a novel gas process for the treatment and purification of a slip stream (approx. 200 Nm3/h) of the raw syngas formed inside the fuel reactor (CFB400) of the CLG pilot plant. Additionally, it will house RWE Power’s Cleaning Test Rig and RWE Power’s Fischer-Tropsch Test Rig. In this way, a representative amount of the produced syngas will be treated to ensure the compliance with the Fischer-Tropsch (FT) synthesis process, and then synthesised in the FT-Reactor.