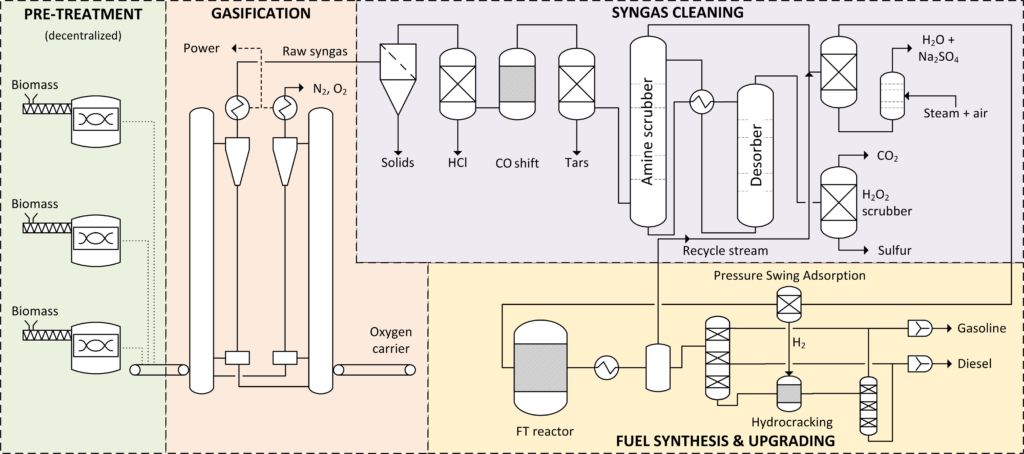

The overall aim of the CLARA project is to develop an efficient technology for the production of liquid fuels based on chemical looping gasification (CLG) of biogenic residues. The major objective of this project is thus to further develop and test CLG up to 1 MWth scale in an industrially relevant environment. Furthermore, the project aims at developing and optimizing innovative technologies for biomass pre-treatment and syngas cleaning. The entire process chain (see below) will be demonstrated by pilot tests including hydrocracking of FT wax for drop-in fuel production. Finally, the process will be evaluated with respect to risks, economics, as well as its impact on environment and society.

The following distinct objectives are defined for this project:

- Develop and test a concept for CLG of biogenic residues for the production of a concentrated syngas stream, at realistic conditions

- Develop concepts for pre-treatment of biogenic residues that will improve the efficiency, operability, and economics of the overall process as well as enlarge the biomass feedstock basis suitable for CLG

- Develop and test a new syngas cleaning technology that meets the specifications for the biofuel synthesis catalyst with respect to impurities and reduces the investment and operating costs of the syngas treatment plant

- Demonstrate the full process chain including pre-treatment of feedstock, CLG gasification, syngas treatment, and fuel synthesis at realistic conditions with a chemical looping gasifier of reasonable scale, i.e. using a 1 MWth dual circulating fluidized bed reactor system

- Demonstrate and optimize road transport drop-in biofuels production (liquid diesel- and gasoline-like) yield and quality via catalytic hydrocracking of FT-wax

- Scale up the entire process including gasifier, syngas treatment, and biofuel synthesis to industrial size using adequate models that have been validated at pilot scale, and optimize the process with respect to conversion efficiency, costs and climate impact

- Estimate the cost structures (investment, operation and maintenance costs, including costs for pre-treatment, transport, fuel production) in comparison to conventional gasification technologies including dynamic cost development due to technological learning, and explore the market potential for the biofuels created by CLG

- Assess the risks of the technology and suggest possibilities for risk mitigation

- Determine the impact of the biomass-to-fuel chain on the environment and society considering the competition with alternative use of biogenic residuals and development of rural areas