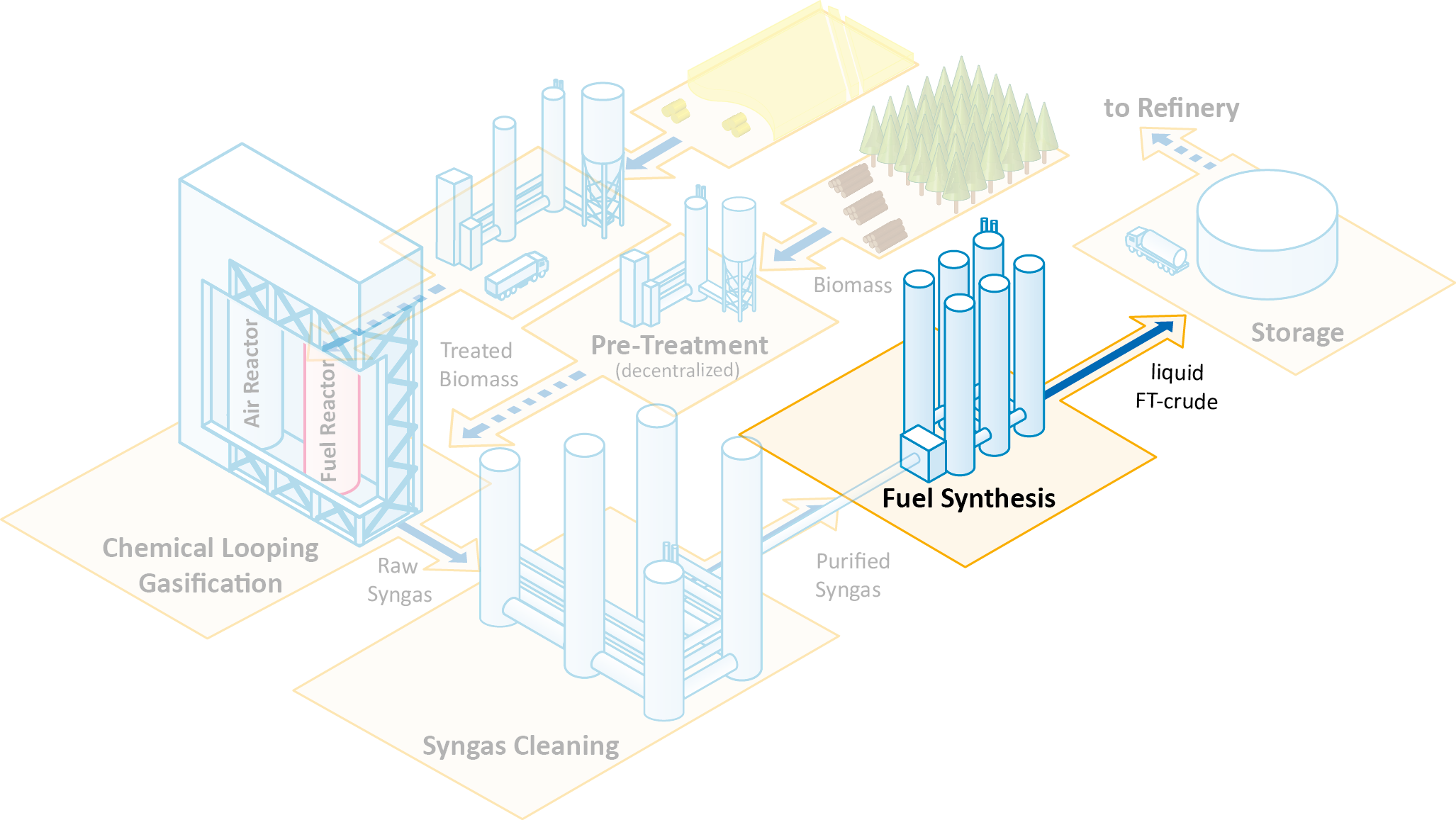

The innovative process sub-units are supplemented by the established Fischer-Tropsch (FT) process, which allows for a continuous conversion of the treated syngas to an easily storable and transportable liquid crude. This process consists of a set of chemical reactions that take place at around 250°C and pressures of 10 to 30 bar and is aided by metal catalysts.

The resulting crude can subsequently be purified and upgraded using conventional refining technologies. As state-of-the-art refineries are available globally, the final fuel upgrading step will be outsourced to existing refineries, which have the required infrastructure and know-how at their disposal and hence can undertake this step efficiently and at minimal cost.