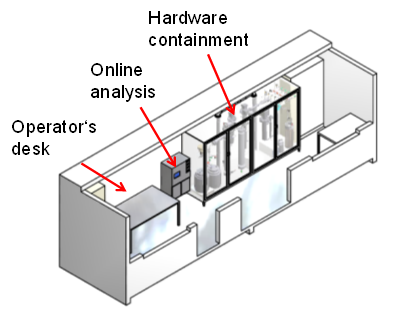

To present the different options for synthesizing basic chemicals from H2 and CO or CO2 containing gases, RWE has deployed a mobile test rig . In a first phase, production of Methane and Methanol has been tested with different commercially available catalysts. For the production of FT crude oil qualities containing liquid and solid components this test rig was improved end of 2017 by a further condenser which is operated at automatically controlled higher temperatures. So also waxes can be condensed to liquid state without blocking the installations.

The feed gas can be a syngas from an upfront gasification plant or a mixture of different pure gases from gas bottles.

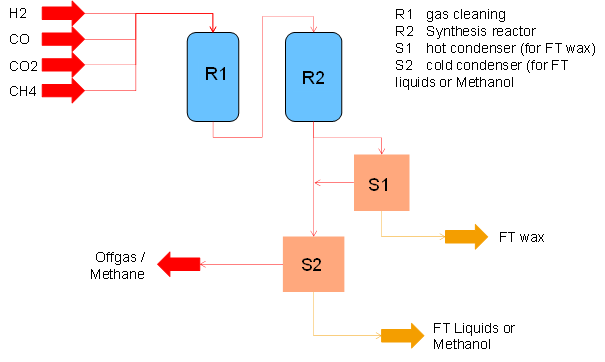

In a first optional reactor R1 (see Synthesis Test Scheme) undesired impurities are filtered or converted to harmless components before entering the main catalytic synthesis reactor R2. Depending on the desired product different catalysts are applied. Also depending on the product the product stream is cooled down in one or two steps. For production of Methane or Methanol a single step cooling/separation S2 takes place by use of cooling water. The off-gas including methane if produced is led to the exhaust while Methanol is condensed and collected for analysis. In case of Fischer Tropsch synthesis a high temperature intermediate cooler / separator S1 is applied to condense and separate the wax fraction. In a second step S2 is applied to condense / separate the liquid hydrocarbons (Naphtha, Diesel, gasoline).